Understanding of the role of pH in filling mezoporous silica with magnetic nanoparticles

Wiktor Wolak

,Mirosław Roman Dudek

,Dinh Quang Ho

,Karol Marcjan

Journal of Applied Mathematics and Computational Mechanics |

Download Full Text |

View in HTML format |

Export citation |

@article{Wolak_2016,

doi = {10.17512/jamcm.2016.1.19},

url = {https://doi.org/10.17512/jamcm.2016.1.19},

year = 2016,

publisher = {The Publishing Office of Czestochowa University of Technology},

volume = {15},

number = {1},

pages = {191--196},

author = {Wiktor Wolak and Mirosław Roman Dudek and Dinh Quang Ho and Karol Marcjan},

title = {Understanding of the role of pH in filling mezoporous silica with magnetic nanoparticles},

journal = {Journal of Applied Mathematics and Computational Mechanics}

}TY - JOUR DO - 10.17512/jamcm.2016.1.19 UR - https://doi.org/10.17512/jamcm.2016.1.19 TI - Understanding of the role of pH in filling mezoporous silica with magnetic nanoparticles T2 - Journal of Applied Mathematics and Computational Mechanics JA - J Appl Math Comput Mech AU - Wolak, Wiktor AU - Dudek, Mirosław Roman AU - Ho, Dinh Quang AU - Marcjan, Karol PY - 2016 PB - The Publishing Office of Czestochowa University of Technology SP - 191 EP - 196 IS - 1 VL - 15 SN - 2299-9965 SN - 2353-0588 ER -

Wolak, W., Dudek, M., Ho, D., & Marcjan, K. (2016). Understanding of the role of pH in filling mezoporous silica with magnetic nanoparticles. Journal of Applied Mathematics and Computational Mechanics, 15(1), 191-196. doi:10.17512/jamcm.2016.1.19

Wolak, W., Dudek, M., Ho, D. & Marcjan, K., 2016. Understanding of the role of pH in filling mezoporous silica with magnetic nanoparticles. Journal of Applied Mathematics and Computational Mechanics, 15(1), pp.191-196. Available at: https://doi.org/10.17512/jamcm.2016.1.19

[1]W. Wolak, M. Dudek, D. Ho and K. Marcjan, "Understanding of the role of pH in filling mezoporous silica with magnetic nanoparticles," Journal of Applied Mathematics and Computational Mechanics, vol. 15, no. 1, pp. 191-196, 2016.

Wolak, Wiktor, Mirosław Roman Dudek, Dinh Quang Ho, and Karol Marcjan. "Understanding of the role of pH in filling mezoporous silica with magnetic nanoparticles." Journal of Applied Mathematics and Computational Mechanics 15.1 (2016): 191-196. CrossRef. Web.

1. Wolak W, Dudek M, Ho D, Marcjan K. Understanding of the role of pH in filling mezoporous silica with magnetic nanoparticles. Journal of Applied Mathematics and Computational Mechanics. The Publishing Office of Czestochowa University of Technology; 2016;15(1):191-196. Available from: https://doi.org/10.17512/jamcm.2016.1.19

Wolak, Wiktor, Mirosław Roman Dudek, Dinh Quang Ho, and Karol Marcjan. "Understanding of the role of pH in filling mezoporous silica with magnetic nanoparticles." Journal of Applied Mathematics and Computational Mechanics 15, no. 1 (2016): 191-196. doi:10.17512/jamcm.2016.1.19

UNDERSTANDING OF THE ROLE OF PH IN FILLING MESOPOROUS SILICA WITH MAGNETIC NANOPARTICLES

Wiktor Wolak 1, Mirosław Roman Dudek 1, Dinh Quang Ho 1,2, Karol Marcjan 1

1

Institute of Physics, University of Zielona Gora

Zielona Góra, Poland

2 Vinh University

Vinh city, Nghe An, Vietnam

20000621@stud.uz.zgora.pl, M.Dudek@if.uz.zgora.pl

hodinhquangdhv@gmail.com, karol.marcjan@gmail.com

Abstract. Computer simulation study of filling pores of mesoporous silica with magnetic iron oxide nanoparticles which are diffusing towards the silica surface from a water solution with a given pH was presented. Three different values of the pH of the solution were under consideration, pH = 4, 7, and 10. The size of nanoparticles was of the order of magnitude of the nanopore diameter. It was observed that in the case of a low concentration of magnetic nanoparticles in the water solution the process of filling the silica pores weakly depends on the pH of the solution. The value of pH becomes only relevant for large concentration of magnetic nanoparticles. In the simulation, a 2-state Potts model was used for preparing the silica matrix. Diffusion of magnetic nanoparticles was restricted to lattice sites only.

Keywords: mesoporous silica, magnetic nanoparticles, point of zero charge

1. Introduction

Recently, an increasing number of engineering applications of magnetic nano-particles can be noted, especially those based on iron oxides which are non-toxic or where the toxicity is negligible. There are materials for medical applications like magnetic resonance [1] or drug release [2] but also new materials for industrial chemistry [3], or materials for environmental protection. In our recent papers [4, 5] we showed the special feature of iron oxide nanoparticles both experimentally and theoretically that when some amount of acid or base is added to an aqueous solution containing magnetic grains, then the solution close to the nanoparticles becomes, respectively, less acidic and less alkaline than it is expected. This property was suggested to be used in the design of new type of mortar with magnetic grains inside [5] achieving an increased compressive strength of mortar as well as its chemical protection against the acidic environment. In the following, we discuss the effect of the pH of water suspension of magnetic nanoparticles on filling the pores of the mesoporous silica. To this aim computer modeling methods have been used.

2. Preparing porous matrix

A series of models of porous glass were

introduced which were studied with the help of computer simulation methods,

like the molecular dynamics method presented in papers [6, 7]. In the

following, we used the Metropolis Monte Carlo method, instead. To model porous

glass, the 2-state Potts model on cubic lattice ![]() was chosen to simulate the phase separation of

a binary mixture by analogy to

a molecular dynamics approach presented in papers [6, 7]. The

following interaction hamiltonian between two kinds of model atoms A and

B of the binary mixture is assumed:

was chosen to simulate the phase separation of

a binary mixture by analogy to

a molecular dynamics approach presented in papers [6, 7]. The

following interaction hamiltonian between two kinds of model atoms A and

B of the binary mixture is assumed:

| (1) |

where lattice sites ![]() ,

, ![]() are occupied by atom

are occupied by atom ![]() (A or B), the angular brackets denote

summation over the nearest-neighbour lattice pairs. In the following, atoms A

represent silica material and atoms B represent vacancies. Hamiltonian in Eq.

(1) is the particular case of the hamiltonian which was introduced in paper [8]

to model the sintering process in metal powders. We assume that

(A or B), the angular brackets denote

summation over the nearest-neighbour lattice pairs. In the following, atoms A

represent silica material and atoms B represent vacancies. Hamiltonian in Eq.

(1) is the particular case of the hamiltonian which was introduced in paper [8]

to model the sintering process in metal powders. We assume that ![]() and

and ![]() .

Initially, atoms A and vacancies B are randomly placed in the sites of a cubic

.

Initially, atoms A and vacancies B are randomly placed in the sites of a cubic ![]() lattice with a given concentration

lattice with a given concentration ![]() of atoms A and

of atoms A and ![]() of

vacan-

cies, and

of

vacan-

cies, and ![]() . During the computer simulation, atoms

and vacancies which are located in the neighbouring lattice sites i, j

can exchange according

to Metropolis rule with a success rate equal to

. During the computer simulation, atoms

and vacancies which are located in the neighbouring lattice sites i, j

can exchange according

to Metropolis rule with a success rate equal to ![]() ,

where

,

where ![]() denotes the energy difference between

the new and old

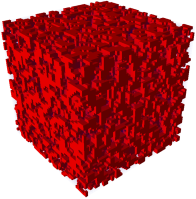

lattice site configuration. In Figure 1, it has been shown the result of Monte

Carlo simulations of a cube with dimension

denotes the energy difference between

the new and old

lattice site configuration. In Figure 1, it has been shown the result of Monte

Carlo simulations of a cube with dimension ![]() lattice sites in x, y, z direction.

The periodic boundary condition was applied.

lattice sites in x, y, z direction.

The periodic boundary condition was applied.

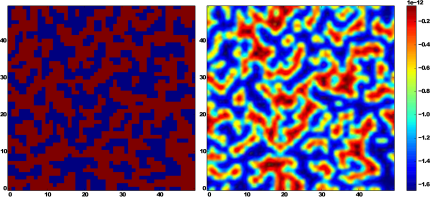

Fig. 1. Result

of N = 600 MC steps of computer simulation of binary alloy of initially

randomly distributed atoms A and B on cubic ![]() lattice.

The parameters

which have been chosen:

lattice.

The parameters

which have been chosen: ![]() ,

,

![]() ,

, ![]() ,

, ![]() K, concentration

of A atoms

K, concentration

of A atoms ![]() . Atoms A (in red) represent model of

porous silica

. Atoms A (in red) represent model of

porous silica

3. Magnetic nanoparticles suspension

In the model, magnetic nanoparticles are

represented by spheres of radius ![]() which can occupy cubic lattice sites. The cubic

lattice is partitioned into two parts where the first one is represented by

silica sites and the remaining sites represent

a solution contacting the silica surface. Each sphere representing magnetic

nano-particle possesses magnetic dipole moment

which can occupy cubic lattice sites. The cubic

lattice is partitioned into two parts where the first one is represented by

silica sites and the remaining sites represent

a solution contacting the silica surface. Each sphere representing magnetic

nano-particle possesses magnetic dipole moment ![]() and a

point charge

and a

point charge ![]() in its center.

The value of charge is the same for each

sphere. It represents the electrostatic charge acquired by iron oxide

material when it is contacting a water solution with a given pH value. Then, there is electrostatic repulsion

between spheres as well as magnetic attraction due to the magnetic

dipolar interaction. The electrostatic part of the inter-

action potential is the following:

in its center.

The value of charge is the same for each

sphere. It represents the electrostatic charge acquired by iron oxide

material when it is contacting a water solution with a given pH value. Then, there is electrostatic repulsion

between spheres as well as magnetic attraction due to the magnetic

dipolar interaction. The electrostatic part of the inter-

action potential is the following:

| (2) |

where ![]() is the distance

between the centers of mass of the nanoparticles located at sites

is the distance

between the centers of mass of the nanoparticles located at sites ![]() and

and ![]() ,

, ![]() represents permittivity,

represents permittivity, ![]() is the Debye length

is the Debye length

| (3) |

![]() denotes

electron charge,

denotes

electron charge, ![]() is the Boltzmann constant,

is the Boltzmann constant, ![]() is the Avogadro number,

is the Avogadro number, ![]() represents ionic strength. It is

assumed that the electrostatic surface

potential of the nanoparticle can be approximated by Nernst potential, which

depends on pH as follows [11]:

represents ionic strength. It is

assumed that the electrostatic surface

potential of the nanoparticle can be approximated by Nernst potential, which

depends on pH as follows [11]:

| (4) |

![]() where is

the gas constant,

where is

the gas constant, ![]() is

the Faraday constant and PZC represents the point of zero charge. In the

following, we have chosen PZC = 7.9 for magnetic nanoparticles

and PZC = 2 for porous matrix representing silica. The surface

charge density is expressed as the following:

is

the Faraday constant and PZC represents the point of zero charge. In the

following, we have chosen PZC = 7.9 for magnetic nanoparticles

and PZC = 2 for porous matrix representing silica. The surface

charge density is expressed as the following:

| (5) |

and it is assumed that ![]() .

.

Magnetic interaction potential represents magnetic dipole-dipole interaction accord- ing to the formula:

| (6) |

where ![]() and

and ![]() represent magnetic moments of

nanoparticles at site

represent magnetic moments of

nanoparticles at site ![]() and

and

![]() ,

respectively. The interaction potentials are complemented by the Lennard-Jones

interaction potential

,

respectively. The interaction potentials are complemented by the Lennard-Jones

interaction potential ![]() which represents the short-ranged

Van der Waals interaction, respectively the magnetic nanoparticle-magnetic

nanoparticle and magnetic nanoparticle-silica in the water solution. In

general, the silica surface will acquire charge

which represents the short-ranged

Van der Waals interaction, respectively the magnetic nanoparticle-magnetic

nanoparticle and magnetic nanoparticle-silica in the water solution. In

general, the silica surface will acquire charge ![]() after

contacting water solution with a given pH which is different from the value of

after

contacting water solution with a given pH which is different from the value of ![]() . In this case, the electrostatic

interaction potential in Eq. (2) is changed to the following one:

. In this case, the electrostatic

interaction potential in Eq. (2) is changed to the following one:

| (7) |

In the model, magnetic nanoparticles in a water

suspension change the orientation of the magnetic moment and jump over

unoccupied cubic lattice sites according to the Metropolis algorithm where the

energy term in ![]() includes

all the interaction potentials. Some

fraction of magnetic nanoparticles penetrates the pores of the silica

surface and sticks to the surface. The concentration of nanoparticles in the

solution was chosen to be equal to

includes

all the interaction potentials. Some

fraction of magnetic nanoparticles penetrates the pores of the silica

surface and sticks to the surface. The concentration of nanoparticles in the

solution was chosen to be equal to ![]() to prevent agglomeration events in the solution.

The diameter of pores was of the order of

magnitude of the dimension of nanoparticle.

to prevent agglomeration events in the solution.

The diameter of pores was of the order of

magnitude of the dimension of nanoparticle.

Fig. 2. On the left,

a two-dimensional projection of the simulated silica surface is shown. Red and

blue rectangles represent silica and pores respectively. On the right,

the corresponding effective interaction potential (electrostatic and Van der

Waals)

is presented which is generated by the silica and felt by nanoparticle with

radius

![]() nm in a solution with

pH = 10 at distance

nm in a solution with

pH = 10 at distance ![]() nm from the silica surface

nm from the silica surface

4. Results and discussion

Magnetic

nanoparticles which are close to silica surface experience pH-dependent electrostatic potential which strongly depends on the distance to

the surface.

In Figure 2, it was shown both the two-dimensional projection of the silica

surface (left panel) and the corresponding effective interaction potential (the

sum of electrostatic interaction potential and Van der Waals interaction

potential) of the simulated silica at ![]() at

the distance

at

the distance ![]() nm (right

panel) which is experienced by a single magnetic nanoparticle with diameter of

5 nm. The question arises to what extent the pH value affects the pore filling

in the case when the size of

the nanoparticle is comparable to the pore diameter.

For such a value of pH

as in Figure 2, magnetic nanoparticles experience strong electrostatic

repulsion but still the Van der Waals attraction is a few orders higher than

the electrostatic one. Our computer simulation suggests that the process of

filling the silica pores by magnetic nanoparticles with dimension of the order

of magnitude of the pore

diameter does not depend on the pH value when the concentration of

nanoparticles in the solution is low. Consequently, the density of

nanoparticles in silica nano-pores weakly depends on the value of pH. It is

evident in Figure 3, where the distribution of magnetic nanoparticles in the

region close to the surface of the porous matrix has been shown for three

values of pH (4, 7, and 10).

nm (right

panel) which is experienced by a single magnetic nanoparticle with diameter of

5 nm. The question arises to what extent the pH value affects the pore filling

in the case when the size of

the nanoparticle is comparable to the pore diameter.

For such a value of pH

as in Figure 2, magnetic nanoparticles experience strong electrostatic

repulsion but still the Van der Waals attraction is a few orders higher than

the electrostatic one. Our computer simulation suggests that the process of

filling the silica pores by magnetic nanoparticles with dimension of the order

of magnitude of the pore

diameter does not depend on the pH value when the concentration of

nanoparticles in the solution is low. Consequently, the density of

nanoparticles in silica nano-pores weakly depends on the value of pH. It is

evident in Figure 3, where the distribution of magnetic nanoparticles in the

region close to the surface of the porous matrix has been shown for three

values of pH (4, 7, and 10).

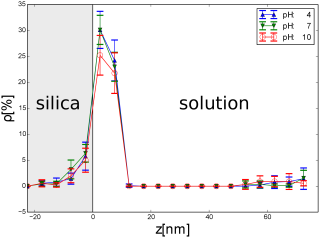

Fig. 3. Space

dependence of the density ![]() of magnetic

nanoparticles in the region close

to the surface of the porous matrix which is contacting solution with a given

value of pH is shown. All nanoparticles have a radius equal to

of magnetic

nanoparticles in the region close

to the surface of the porous matrix which is contacting solution with a given

value of pH is shown. All nanoparticles have a radius equal to ![]() nm.

Three values of pH were chosen, pH = 4, 7, and 10

nm.

Three values of pH were chosen, pH = 4, 7, and 10

There is no significant difference between the fragments of the plots corresponding to the interior of silica. The effective potential experienced by magnetic nanoparticles approaching the silica surface strongly depends on their distance to the surface. In the case of large concentration of magnetic nanoparticles, the role of the value of pH increases. In paper [10], the preferential filling the silica pores by the alkaline solution with magnetic nanoparticles was observed. The results strongly depend on the value of PZC of the materials under consideration. In particular, in the case of magnetic iron oxide nanoparticles can take the value between 6.3 [5] and 7.9 [11]. In a magnetic suspension with the large concentration of magnetic nanoparticles, the dipolar magnetic interactions become important and they compete with the pH-dependent electrostatic repulsion between the nanoparticles.

5. Conclusions

A computer simulation of the process of filling the nanopores of the silica glass by water magnetic suspension at given value of pH was under discussion. It was concluded that pH value is significant for the surface adsorption of the nanoparticles but filling the pores by them weakly depends on the value of pH in the case of low concentration of magnetic nanoparticles.

Acknowledgements

We thank Bartłomiej Zapotoczny for his discussion and comments on the work.

References

[1] Lodhia J., Mandarano G., Ferris N.J., Eu P., Cowell S.F., Development and use of iron oxide nanoparticles (Part 1): Synthesis of iron oxide nanoparticles for MRI, Biomed. Imaging and Intervention Journal 2010, 6(2), e12.

[2] Huang S., Li C., Cheng Z., Fan Y., Yang P., Zhang C., Yang K., Lin J., Magnetic Fe3O4 mesoporous silica composites for drug delivery and bioadsorption, J. Colloid. Interf. Sci. 2012, 376, 312-321.

[3] Lu A.H., Salabas E.L., Schuth F., Magnetic nanoparticles: Synthesis, protection, functionalization, and application, Angew. Chem. Int. Ed. 2007, 46, 1222-1244.

[4] Zapotoczny B., Dudek M.R., Koziol J.J., Mleczko J., Nanobuffering property of Fe3O4 magnetic nanoparticles in aqueous solution, Physica A 2013, 392, 1493-1499.

[5] Borucka-Lipska J., Kiernozycki W., Guskos N., Dudek M.R., Ho D.Q., Wolak W., Marc M., Koziol J.J., Kalaga J.K., Investigation on magnetite concentrate with respect to its use in concrete, submitted.

[6] Gelb L.D., Gubbins K.E., Characterization of porous glasses: Simulation models, adsorption isotherms, and the Brunauer-Emmett-Teller analysis method, Langmuir 1998, 14(8), 2097-2111.

[7] Gelb L.D., Gubbins K.E., Pore size distributions in porous glasses: a computer simulation study, Langmuir 1999, 15(2), 305-308.

[8] Dudek M.R., Gouyet J.F., Kolb M., Q+ 1 state Potts model of late stage sintering, Surface Science 1998, 401(2), 220-226.

[9] Keren R., Sparks D.L., Effect of pH and ionic strength on boron adsorption by pyrophyllite, Soil Science Society of America Journal 1994, 58(4), 1095-1100.

[10] Zapotoczny B., Dudek M.R., Guskos N., Kozio J.J., Padlyak B.V., Kosmider M., Rysiakiewicz- -Pasek E., FMR study of the porous silicate glasses with Fe3O4 magnetic nanoparticles fillers, Journal of Nanomaterials 2012, 8.

[11] Tombacz E., Majzik A., Horvat Z.S., Illes E., Magnetite in aqueous medium: coating its surface and surface coated with it, Romanian Reports in Physics 2006, 58(3), 281-286.